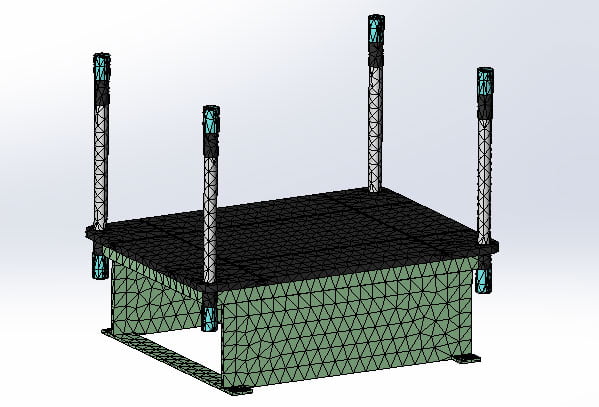

Tie Rod Type Hydraulic Press offered by us is made available in 2 as well as 4-post column designs and are made available in tonnage capacities of up to 1500 tons. Being part of modern hydraulic presses, these offer better performance and process reliability with lesser maintenance needs. Further, the presses also feature latest technology based fast acting valves, hydraulic circuits, electrical components and other process support components that help in gaining an enhanced performance from these hydraulic presses. Its unique construction makes the press suited for light to medium and heavy duty work that does not involve lateral (side) loads. Here, our expertise lies in making these available in a wide range of bore sizes for handling the demands of medium and heavy services.

General Overview

Mechanical Construction

In order to mate the latest demand of customers with various layout demand of customers with layout specifications, MICRO design team equipped with latest software SOLID WORKS through which any elastricity by strain-gauges ensuring that the critical points of the structure are stressed kept with in limit after adopting new technology MHPL team capable to design and produce presses which are extremely rigid in structure .The specific concept of open and compact makes MHPL presses highly flexible for inline use. The main slide is completely guided by prismatic jibs or by linear sliding block with adjustable backlash for high working precision 16sliding blocks incorporating adjustable backlash can also be incorporating for more precision in main bed.

Hydraulics

Micro Team is having a vast exposure in designing of any kind of complicated circuit . MHPL team has the capability of designing the hydraulic circuits with various control valves and pumps such as proportional and servo valves . The manifolds are designed in latest software .

Application:

Tie-Rod Construction Hydraulic Presses are extensively used in areas like :

- Machine Tools

- Food & Processing

- Engineering industry

- Agricultural

- Mining

- Earth moving applications

Download Technical Specification of Triple Action Scrap Baling

| TECHNICAL SPECIFICATIONS | |||||||||||

| Item | Unit | MHPL 60T | MHPL 80T | MHPL 100T | MHPL 150T | MHPL 200T | MHPL 300T | MHPL 500T | MHPL 600T | MHPL 1000T | |

| Tonnage | Ton | 60 | 800 | 100 | 150 | 200 | 300 | 500 | 600 | 1000 | |

| Max Workng Pressure | Kg/cm2 | 250 | 250 | 250 | 250 | 250 | 250 | 25 | 25 | 25 | |

| Max.travel distance of moveable workbench | mm | 110 | 110 | 140 | 140 | 160 | 160 | 160 | 250 | 160 | |

| Max.distance between workbench and upper beam | mm | 275 | 275 | 350 | 350 | 380 | 380 | 420 | 500 | 500 | |

| Speed of speedy lifting of workbench | mm/s | 135 | 135 | 135 | 135 | 180 | 150 | 140 | 125 | 88 | |

| Speed of pressure withdraw of workbench | mm/s | 7.4 | 6.1 | 4.5 | 3 | 2-4.5 | 1.8-4 | 1.5-2.5 | 06-Feb | 2 | |

| Speech of speedy withdraw of workbench | mm/s | 200 | 200 | 180 | 150 | 150 | 180 | 135 | 175 | 90 | |

| Nominal pressure of material return tank | Kg/cm2 | 20 | 20 | 50 | 50 | 50 | 60 | 100 | 100 | 150 | |

| Effective area of workbench | L-R | mm | 300 | 335 | 340 | 440 | 495 | 620 | 670 | 710 | 1200 |

| F-B | mm | 400 | 400 | 420 | 450 | 510 | 650 | 700 | 700 | 1200 | |

| Flow of hydraulic pump | L/min | 14.4 | 14.4 | 14.4 | 14.4 | 24-Oct | 14-36 | 18-36 | 92 | 54 | |

| Power of Motor | KW | 5.5 | 5.5 | 5.5 | 5.5 | 7.5(6*) | 7.5 | 11 | 18.5 | 22(6*) | |

| Overall dimension(L-RxF-BxH | mm | 1010 | 1020 | 1070 | 1190 | 1280 | 1430 | 1570 | 1880 | 2900 | |

| X1000 | X1000 | X1000 | X1000 | X1000 | X1000 | X1000 | X1200 | X2000 | |||

| X1165 | X1195 | X1380 | X1490 | X1660 | X1820 | X2195 | X2432 | X4030 | |||

| kg | 1000 | 1100 | 1500 | 2000 | 2800 | 4700 | 7600 | 12000 | 22000 | ||

| Optional Equipment : | |

| 1 | Heavy-duty benches |

| 2 | Bench casters |

| 3 | Special PLC’s |

| 4 | Timers & counters |

| 5 | Automatic press cycles |

| 6 | Feed integration packages |

| 7 | Digital pressure readout |

| 8 | Ram position control systems |

| 9 | PQA (Part Quality Assurance) |

| 10 | Heat exchanger upgrades |

| 11 | Hydraulic power unit upgrades |

| 12 | Speed control |

| 13 | Robot Integration |

| 14 | PMA (Preventative Maintenance Assistant) |

| 15 | Frame modifications |

| 16 | Automatic Lube System |

| 17 | Die Protection Sensor Inputs |

Salient Feature

- Rust Proof

- Excellent strength

- Reliable

- Easy installation

- Dimensionally accurate

- Low noise operation

The latest technologies that are being used in manufacturing are

- Valves that are fast acting

- Electrical components

- Hydraulic circuits

Apart from the above mentioned components, there are various other process support components that will help in gaining better performance from the hydraulic presses that we have manufactured. Moreover, no matter what the requirement of the client is, we deliver the products on time.

- Overview

General Overview

Tie Rod Type Hydraulic Press offered by us is made available in 2 as well as 4-post column designs and are made available in tonnage capacities of up to 1500 tons. Being part of modern hydraulic presses, these offer better performance and process reliability with lesser maintenance needs. Further, the presses also feature latest technology based fast acting valves, hydraulic circuits, electrical components and other process support components that help in gaining an enhanced performance from these hydraulic presses. Its unique construction makes the press suited for light to medium and heavy duty work that does not involve lateral (side) loads. Here, our expertise lies in making these available in a wide range of bore sizes for handling the demands of medium and heavy services.

Mechanical Construction

In order to mate the latest demand of customers with various layout demand of customers with layout specifications, MICRO design team equipped with latest software SOLID WORKS through which any elastricity by strain-gauges ensuring that the critical points of the structure are stressed kept with in limit after adopting new technology MHPL team capable to design and produce presses which are extremely rigid in structure .The specific concept of open and compact makes MHPL presses highly flexible for inline use. The main slide is completely guided by prismatic jibs or by linear sliding block with adjustable backlash for high working precision 16sliding blocks incorporating adjustable backlash can also be incorporating for more precision in main bed.

Hydraulics

Micro Team is having a vast exposure in designing of any kind of complicated circuit . MHPL team has the capability of designing the hydraulic circuits with various control valves and pumps such as proportional and servo valves . The manifolds are designed in latest software .

- Images

- Videos

- Applications

Application:

Tie-Rod Construction Hydraulic Presses are extensively used in areas like :

- Machine Tools

- Food & Processing

- Engineering industry

- Agricultural

- Mining

- Earth moving applications

- Tech Specs

Download Technical Specification of Triple Action Scrap Baling

TECHNICAL SPECIFICATIONS Item Unit MHPL

60TMHPL

80TMHPL

100TMHPL

150TMHPL

200TMHPL

300TMHPL

500TMHPL

600TMHPL

1000TTonnage Ton 60 800 100 150 200 300 500 600 1000 Max Workng Pressure Kg/cm2 250 250 250 250 250 250 25 25 25 Max.travel distance of moveable workbench mm 110 110 140 140 160 160 160 250 160 Max.distance between workbench and upper beam mm 275 275 350 350 380 380 420 500 500 Speed of speedy lifting of workbench mm/s 135 135 135 135 180 150 140 125 88 Speed of pressure withdraw of workbench mm/s 7.4 6.1 4.5 3 2-4.5 1.8-4 1.5-2.5 06-Feb 2 Speech of speedy withdraw of workbench mm/s 200 200 180 150 150 180 135 175 90 Nominal pressure of material return tank Kg/cm2 20 20 50 50 50 60 100 100 150 Effective area of workbench L-R mm 300 335 340 440 495 620 670 710 1200 F-B mm 400 400 420 450 510 650 700 700 1200 Flow of hydraulic pump L/min 14.4 14.4 14.4 14.4 24-Oct 14-36 18-36 92 54 Power of Motor KW 5.5 5.5 5.5 5.5 7.5(6*) 7.5 11 18.5 22(6*) Overall dimension(L-RxF-BxH mm 1010 1020 1070 1190 1280 1430 1570 1880 2900 X1000 X1000 X1000 X1000 X1000 X1000 X1000 X1200 X2000 X1165 X1195 X1380 X1490 X1660 X1820 X2195 X2432 X4030 kg 1000 1100 1500 2000 2800 4700 7600 12000 22000 Optional Equipment : 1 Heavy-duty benches 2 Bench casters 3 Special PLC’s 4 Timers & counters 5 Automatic press cycles 6 Feed integration packages 7 Digital pressure readout 8 Ram position control systems 9 PQA (Part Quality Assurance) 10 Heat exchanger upgrades 11 Hydraulic power unit upgrades 12 Speed control 13 Robot Integration 14 PMA (Preventative Maintenance Assistant) 15 Frame modifications 16 Automatic Lube System 17 Die Protection Sensor Inputs - Salient Feature

Salient Feature

- Rust Proof

- Excellent strength

- Reliable

- Easy installation

- Dimensionally accurate

- Low noise operation

The latest technologies that are being used in manufacturing are

- Valves that are fast acting

- Electrical components

- Hydraulic circuits

Apart from the above mentioned components, there are various other process support components that will help in gaining better performance from the hydraulic presses that we have manufactured. Moreover, no matter what the requirement of the client is, we deliver the products on time.

- Mfg. Process

- Enquiry